What We Do

Inspection Facilities

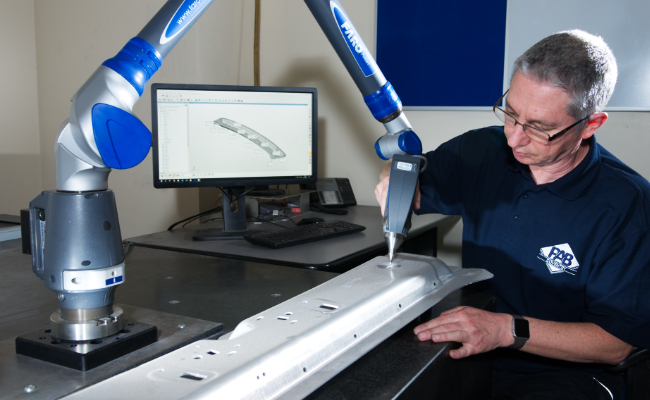

PAB Inspection

We don’t consider any job finished until the items in question have been inspected to the highest possible standards and passed. The accreditations we’ve been awarded reflect our commitment to excellence in all aspects of our work, and are freely available for any client to download and examine. We never rest on our laurels, however, because we know that delivering excellence relies upon never letting standards slip. To make sure that they never do, we impose a strict inspection regime, making full use of the expertise of our time served workforce combined with the latest technology to examine each component in depth before we decide it meets our exacting standards.

- +44 (0)24 7669 4419

- info@pabcoventry.co.uk

Cutting Edge Laser Inspection

The forces and techniques used in pressing, cutting or forming sheet metal can sometimes result in flaws or faults that are difficult to spot. The good news is that the laser inspection technology we employ can scan every item in depth from every angle, producing a comprehensive picture capturing the vital details and making it easy to pick up on anything which is less than 100% correct.

PPAP requirements

The Production Part Approval Process (PPAP) is utilised throughout the automotive industry in order to ensure that component suppliers such as PAB work to the standards expected of a client and will deliver components that are ready to enter the supply chain and deliver the specification needed as and when a client requires.

FARO Arm

The best qualified inspectors deserve the finest tools and that’s what the team at PAB get to work with. The FaroArm represents the accepted standard in arm technology. It was specifically designed and manufactured to offer precise and convenient 3D measurements of components, confirming that they meet the specifications originally set out in the design.

We also utilise state of the art coordinate measuring machines (CMM) and industry leading Creaform laser systems to ensure that the inspection of every single component we produce is detailed, in-depth and accurate. When we hand a component over to a client, they can be certain that it’s up to the task in hand.

Standard CTA

Multiple shift support

Our flexible working patterns allow us to deliver inspections whenever needed, ensuring that the components a client needs are passed and delivered to the strictest possible timetable.

Trained and Qualified Auditors

The auditors on the PAB team have been trained and are compliant with the International Automotive Task Force (IATF) standard 16949. This is an internationally recognised standard which sets the expected requirements of a quality management system for any organisation involved in the automotive industry.

Need Laser Cutting In The West Midlands, Coventry And Birmingham? Just Click Your Location For More.

Need Metal Cutting? We Help Businesses Across The West Midlands, Including Coventry & Birmingham.

For more information please call us on +44 (0)24 7669 4419 or email info@pabcoventry.co.uk